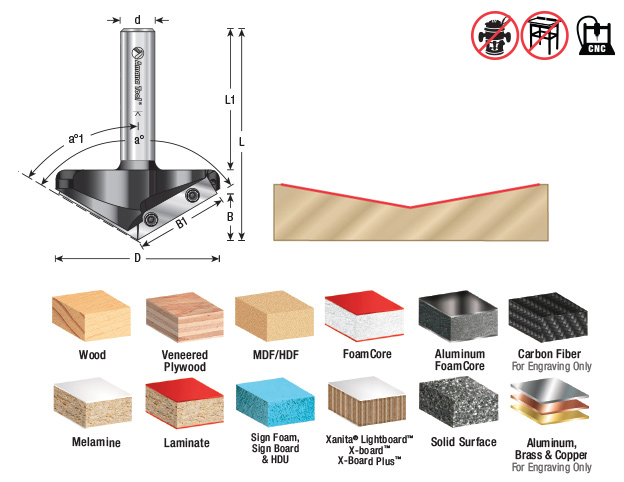

RC-1111 Insert V-Groove 140 Deg x 3-5/64 Dia x 1/2 x 1/2 Inch Shank CNC

$289.62

Usually ships on the 2nd business day from order date.

| (a°) Angle | 140° |

|---|---|

| A1° | 70° |

| Diameter (D) | 3-5/64 |

| (B) Cutting Height | 1/2 |

| B1 | 1-1/2 |

| Cutting Edges | 1 |

| (d) Shank | 1/2 |

| Overall Length (L) | 3-3/16 |

| L1 | 1-31/32 |

| Max Rpm | 16,000 |

| Flutes | 2 |

| # Of Knives | 2 |

Description

The innovative CNC tool design uses the highest grade carbide insert knife. These industrial V-Groove insert router bits were especially designed for applications including:

- Miter folds – “create the perfect joint”

- Signmaking and lettering

Excellent for cutting:

- Aluminum, Brass, Bronze, Copper, Gold, Silver & Carbon Fiber

(Engraving Only) - Acrylic/Plastic

- Composites

- Composite Decking

- Epoxy (Epoxy Resins)

- Foam

- High Density Polyethylene (HDPE)

- Laminate

- Melamine

- MDF/HDF

- PVC

- Sign Board

- Solid Surface

- Veneered Plywood

- Wood

- Xanita® Board*

- 20lbs High Density Urethane

Advantages of Insert Tooling:

- Long lasting insert knives provide superior smooth quality cuts every time

- Quick and precise replacements of dull knives

- Due to insert accuracy tool life is extended

- Insert tooling allows for harder grades of carbide

- Special carbide grades for special applications

- Knives can be re-sharpened multiple times without affecting the original profile

- Cost effective solution compared to replacing brazed router bits

Secure locking screw system ensures maximum safety and maintains cutting accuracy. CNC router requires quality hold downs to ensure the least possibility of material shifting during operation.

Warning: Before using any insert tool, make sure the set screw is tightened firmly. When replacing a dull insert, first clean the tool and remove all dust prior to inserting the new knife.

Specifications

| (a°) Angle | 140° |

| a1° | 70° |

| (D) Diameter | 3-5/64 |

| (B) Cutting Height | 1/2 |

| B1 | 1-1/2 |

| Cutting Edges | 1 |

| (d) Shank | 1/2 |

| Overall Length (L) | 3-3/16 |

| L1 | 1-31/32 |

| Max RPM | 16,000 |

| Flutes | 2 |

| # of knives | 2 |