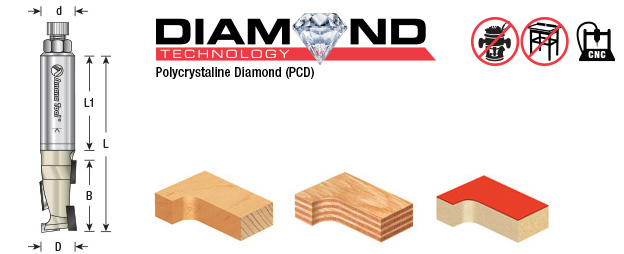

DRB-200 CNC Polycrystalline Diamond (PCD) Tipped Compression Up/Down Shear R/H Direction 1/2 Dia x 1 Inch x 1/2 Shank Router Bit

$244.64

| Diameter (D) | 1/2 |

|---|---|

| (B) Cutting Height | 1 |

| Shank (d) | 1/2 |

| Overall Length (L) | 2-3/4 |

| Max Rpm | 18,000 |

| L1 | 1-3/8 |

| # Of Knives | 1+1 |

Description

Diamond is the hardest material on the earth. Polycrystalline Diamond (PCD) tooling is manufactured in a high-temperature and high-pressure laboratory that fuses diamond particles onto a carbide substrate, which allows the diamond to be brazed onto a tool body.

If you’re looking for the ultimate in tooling you’ve found it! Amana Tool®’s PCD tipped compression CNC router bits will groove joint and rabbet a wide variety of tough abrasive materials including composites, particleboard, MDF (both raw or with melamine), veneer and hardwoods. The cutting edge lasts much longer than carbide for extremely long life.

Multipliers for different materials:

Chipboard without coating: Max RPM x 1.1%

Cross grain veneer: Max RPM x 0.7%

MDF: Max RPM x 0.8%

Excellent for Cutting:

- Aluminum

- Aluminum Composites

- Aluminum Composite Material (ACM)

- Composites

- Composite Panels

- Custom Composite Materials (CCM)

- Fiberglass

- Fiberglass PCB Board

- Fiberglass Reinforced Composites

- Fiber-Reinforced Urethane

- Fiber-Reinforced Structural Foam Floors

- Hard and Soft Wood

- Lightweight Composites

- MDF

- Plastic

Benefits of Diamond Technology

- Harder cutting edge provides higher resistance to wear

- Cut thousands of feet more than carbide without changing tool saving setup time

- Optimized machine tool efficiency

- Quality of finish is often significantly improved

Specifications

| Diameter (D) | 1/2 |

| (B) Cutting Height | 1 |

| Shank (d) | 1/2 |

| Overall Length (L) | 2-3/4 |

| Max RPM | 18,000 |

| L1 | 1-3/8 |

| # of knives | 1+1 |