CanCam Z540

Vertical machining center, VMC Machine, VMC Canada

CanCam Z540

Vertical machining center, VMC Machine, VMC Canada

Single phase - $50,000 | 3 phase - $53,500

Description

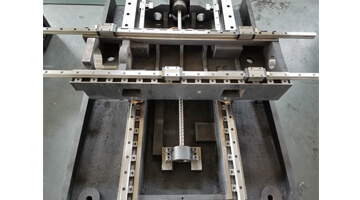

Uncover the cutting-edge features of the CanCam Z540 CNC machine, designed to elevate your precision machining to new heights. From its robust build to high-speed capabilities, we delve into how these features enhance productivity and quality. Some of the VMC machines advanced technology we would like to bring attention to is the PMI precision ballscrew and linearguideway coupled with an NSK bearing and rigid build ensure flawless results for even the most intricate machining tasks.

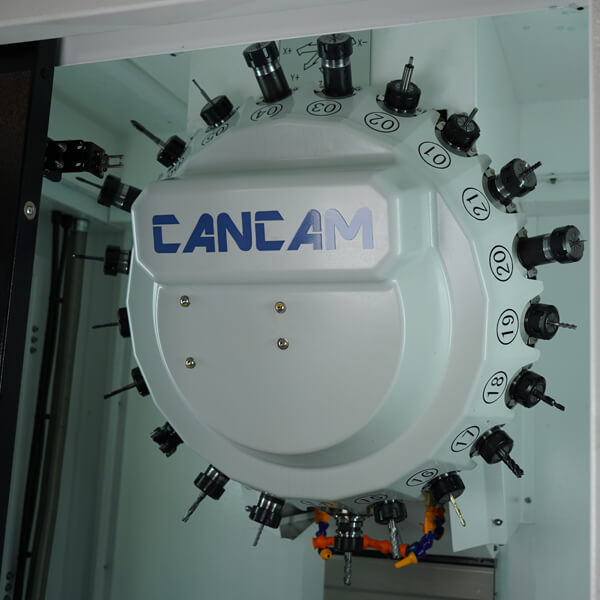

The controller of choice is an industry leader Fanuc 0i MF Plus, the ATC mechanism is a Sanjet servo driven radial magazine with 21 tool locations.

Streamline your production processes and optimize efficiency with the CanCam Z540 CNC machine. Unlock faster turnaround times, reduce costs, and boost output with this advanced machining solution. Explore the path to enhanced productivity now.

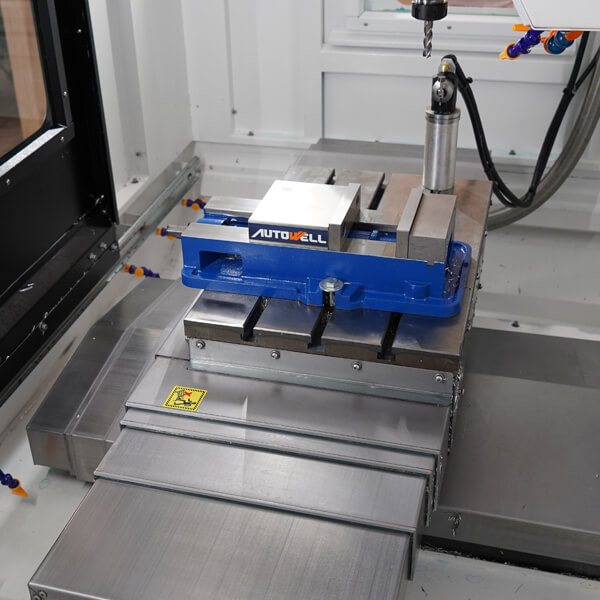

Equipped with a BT30 inline CELLS 5.5kw spindle,providing a seamless coolant supply to enhance cutting performance and extend tool life. The machine’s capability enables efficient chip evacuation and minimizes heat build-up during machining, ensuring optimal tool performance and surface finish. Should you require the CNC as a single phase cnc milling machine it would be equipped with a CELLS 3.7Kw spindle.

The CanCam Z540 delivers exceptional performance and versatility in machining operations. The machine’s robust construction ensures stability and precision, allowing for high-speed machining while maintaining superior accuracy. Whether it’s milling, drilling, or contouring, the CanCam Z540 is engineered to handle a diverse range of machining tasks with ease.

The CanCam Z540 VMC comes ready with a high precision tool setter system and a infrared touch probe.

Furthermore, the CanCam Z540 features an intuitive and user-friendly pendant control interface, streamlining operation and facilitating ease of use. With tool changes at 1.8s and a servo driven radial magazine ATC holder boasts a 21 tool bank capacity to ensure speed and productivity.

With its high-quality components and precise engineering, the CanCam Z540 VMC promises reliable and consistent results, making it an ideal choice for various industries and machining applications. Whether you’re a seasoned CNC professional or just starting in the world of machining, the CanCam Z540 offers a seamless and efficient machining experience.

the VMC is ideally configured for high-speed rigid tapping applications, capable of achieving spindle speeds of up to 5000 RPM. This characteristic can be attributed to its well-engineered spindle design and is recognized for contributing significantly to the efficient execution of high-precision machining operations.

This CNC machine is also available as a single phase cnc milling machine, the CanCam Z540 is built to meet the demands of modern manufacturing, providing a perfect blend of performance, efficiency, and reliability. Invest in the CanCam Z540 VMC to elevate your machining capabilities and achieve outstanding results for your projects.

Product Features

| Single phase or 3 phase power This can be outfitted as a Single phase VMC or a 3 Phase VMC

|

| Durable Casting And Components The cutting-edge design of casting employs meticulous annealing processes in harmony with conventional aging techniques for each casting. This intricate blend of methodologies fosters exceptional vibration damping, while simultaneously ensuring long-term stability, thereby promising the consistent delivery of quality outcomes. Such an approach reflects the growing adoption of advanced manufacturing procedures, which prioritize the mitigation of adverse vibrations and promote the longevity of machine components. It’s this rigorous adherence to precision and quality that sets our casting process apart, transforming the landscape of the industry with innovation and strategic application of proven methodologies.

|

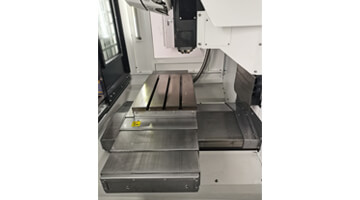

| Cast Iron Bed Our meticulously machined cast iron bed features an integrated design with three T-slot tracks, providing a robust platform for versatile workholding solutions. This sophisticated equipment is designed with precision in mind, offering an unparalleled basis for operations that necessitate reliable and accurate workholding. The inclusion of the T-slot tracks provides users with the flexibility to secure workpieces of various shapes and sizes effectively, enhancing the overall productivity and efficiency of their operations. Moreover, the combination of cast iron’s inherent strength with precision grounding ensures the bed’s longevity, making it an invaluable asset to your production line.

|

| Tool Changer The state of the art, 21-tool Servo Driven Radial Magazine guarantees a smooth and rapid tool change process. This sophisticated piece of machinery demonstrates a remarkable tool change time of just 1.8 seconds per transition, a testament to its efficient design and engineering prowess. The radial magazine is driven by a high-precision, low-backlash reducer coupled with a rear-mount servo motor drive. This combination ensures a balanced distribution of gravity and facilitates convenient motor replacement. Furthermore, the Servo Driven Radial Magazine benefits from its unique tool pot design which mitigates pot tilting stroke and enhances the product’s lifespan.

|

| Tool Setter Our 3D Touch Trigger Tool Setter is designed to expedite the measuring process and enhance the performance of your machining centers. It focuses on delivering rapid measurements of tool length and diameter, thereby streamlining your operations and significantly cutting down setup times. You can expect an impressive repeatability of 1.00 μm 2σ, ensuring precise measurements every time.

|

| Touch Probe The probe is designed to improve machine tool manufacturing efficiency, reduce machine downtime awaiting first-off inspection results, and mitigate the impact of fixture and incoming material errors. This touch probe uses the kinematic resistive principle, a proven technology for stable, long-term operation. It provides highly precise measurements.

|

| Wash down nozzles The machine reservoir is designed with six strategically placed nozzles to facilitate the effective expulsion of metal shavings into the designated chip disposal compartments. This configuration allows for the efficient management of metal waste, thereby ensuring a smooth operational process that minimizes downtime.

|

| Coolant nozzles The numerous coolant nozzles in our design offer notable enhancements to machining efficiency, including superior surface finish, optimized chip evacuation, and improved cooling of the tool.

|

| Electrical Cabinet The electronic components of the machine, which are conveniently accessible, are sourced exclusively from industry-leading manufacturers. These include but are not limited to Lovato, Schneider, Fanuc, and Delta, thereby ensuring high performance and reliability.

|

| Leveling Feet Our robust and industrially engineered leveling feet provide a precise means of adjusting machine alignment, ensuring optimal operational performance and stability. Leveling feet play a crucial role in stabilizing machinery, especially on uneven surfaces. Misalignment can lead to sliding, excessive wear, and even serious safety issues for operator

|

- mm

- inch

Specification

Physical Features

| Machining Bed Width/Length | 600mm x 400mm |

| X Axis Travel | 500 mm |

| Y Axis Travel | 400mm |

| Max. Table load | 250kg |

| Spindle nose to table | 155 - 455mm |

| Spindle center to column | 465mm |

| X/ Y/ Z axis Rapid Traverse | 48 m/min |

| Table Top | T - Slot Cast Iron |

| Tool Capacity | 21 |

| Centralized Lubrication | Included |

| Leveling Feet | Included |

| Touch Probe | Infrared Touch Probe |

| Auto Tool Touch off-Fixed Position | Included |

| Machine Footprint | 1800×2230×2300mm |

| Net Weight | 5730 lbs/2600 kg |

| Gross Weight | 6170 lbs/2800 kg |

Power

| Sinlge Phase Voltage | 14.2Kw 220V Single phase (3.7Kw Spindle) |

| 3 Phase Voltage | 16Kw 208v 3 phase / 16Kw 380v 3 phase |

Controller

| Interface | Fanuc 0i MF Plus (3 phase) / GSK GSK218MC-V (Single phase) |

| Type | Industrial |

| Screen Size | 381 mm LED |

| Operating System | Dedicated |

| Inputs | USB / CF Card |

| MPG Handwheel | Included |

| Ethernet | Included |

| Controller Upgrade Option | N/A |

Standard Spindle

| Model | CELLS |

| Power | 5.5 Kw / 7.4 HP (3 phase) / 3.7Kw / 4.96 HP (Single phase) |

| Max Speed | 12000 RPM (3 phase) / 10000 RPM (Single phase) |

| Tool Holder | BT30 |

| Cooling System | Oil Cooled |

| Tool Change Type | Automatic |

| Tool Holder Positions | 21 |

Drive System

| Motor | Fanuc Absolute Servos (3 phase) / GSK Absolute Servos (Single phase) |

| Transmission | X Y Z axis - PMI ballscrews and linear guides |

Speed

| Rapid Speed XY | 1890 IPM |

| Rapid Speed Z | 1890 IPM (1260 IPM for single phase) |

| Max Cutting Speed | 550 IPM |

Tool Calibrator

| Fixed Position | Included |

| Touch Probe | Included |

Accuracy

| Positioning | 0.006 mm |

| Repositioning | 0.002 mm |

Physical Features

| Machining Bed Width/Length | 24in x 16in |

| X Axis Travel | 19.685 In |

| Y Axis Travel | 15.748 In |

| Max. Table load | 250kg |

| Spindle nose to table | 6.102 - 17.913 In |

| Spindle center to column | 18.307 In |

| X/ Y/ Z axis Rapid Traverse | 1890 in/min |

| Table Top | T - Slot Cast Iron |

| Tool Capacity | 21 |

| Centralized Lubrication | Included |

| Leveling Feet | Included |

| Touch Probe | Infrared Touch Probe |

| Auto Tool Touch off-Fixed Position | Included |

| Machine Footprint | 70.866×87.795×90.551in |

| Net Weight | 5730 lbs/2600 kg |

| Gross Weight | 6170 lbs/2800 kg |

Power

| Sinlge Phase Voltage | 14.2Kw 220V Single phase (3.7Kw Spindle) |

| 3 Phase Voltage | 16Kw 208v 3 phase / 16Kw 380v 3 phase |

Controller

| Interface | Fanuc 0i MF Plus (3 phase) / GSK GSK218MC-V (Single phase) |

| Type | Industrial |

| Screen Size | 15 inch LED |

| Operating System | Dedicated |

| Inputs | USB / CF Card |

| MPG Handwheel | Included |

| Ethernet | Included |

| Controller Upgrade Option | N/A |

Standard Spindle

| Model | CELLS |

| Power | 5.5 Kw / 7.4 HP (3 phase) / 3.7Kw / 4.96 HP (Single phase) |

| Max Speed | 12000 RPM (3 phase) / 10000 RPM (Single phase) |

| Tool Holder | BT30 |

| Cooling System | Oil Cooled |

| Tool Change Type | Automatic |

| Tool Holder Positions | 21 |

Drive System

| Motor | Fanuc Absolute Servos (3 phase) / GSK Absolute Servos (Single phase) |

| Transmission | X Y Z axis - PMI ballscrews and linear guides |

Speed

| Rapid Speed XY | 1890 IPM |

| Rapid Speed Z | 1890 IPM (1260 IPM for single phase) |

| Max Cutting Speed | 550 IPM |

Tool Calibrator

| Fixed Position | Included |

| Touch Probe | Included |

Accuracy

| Positioning | 0.00023 in |

| Repositioning | 0.00078 in |