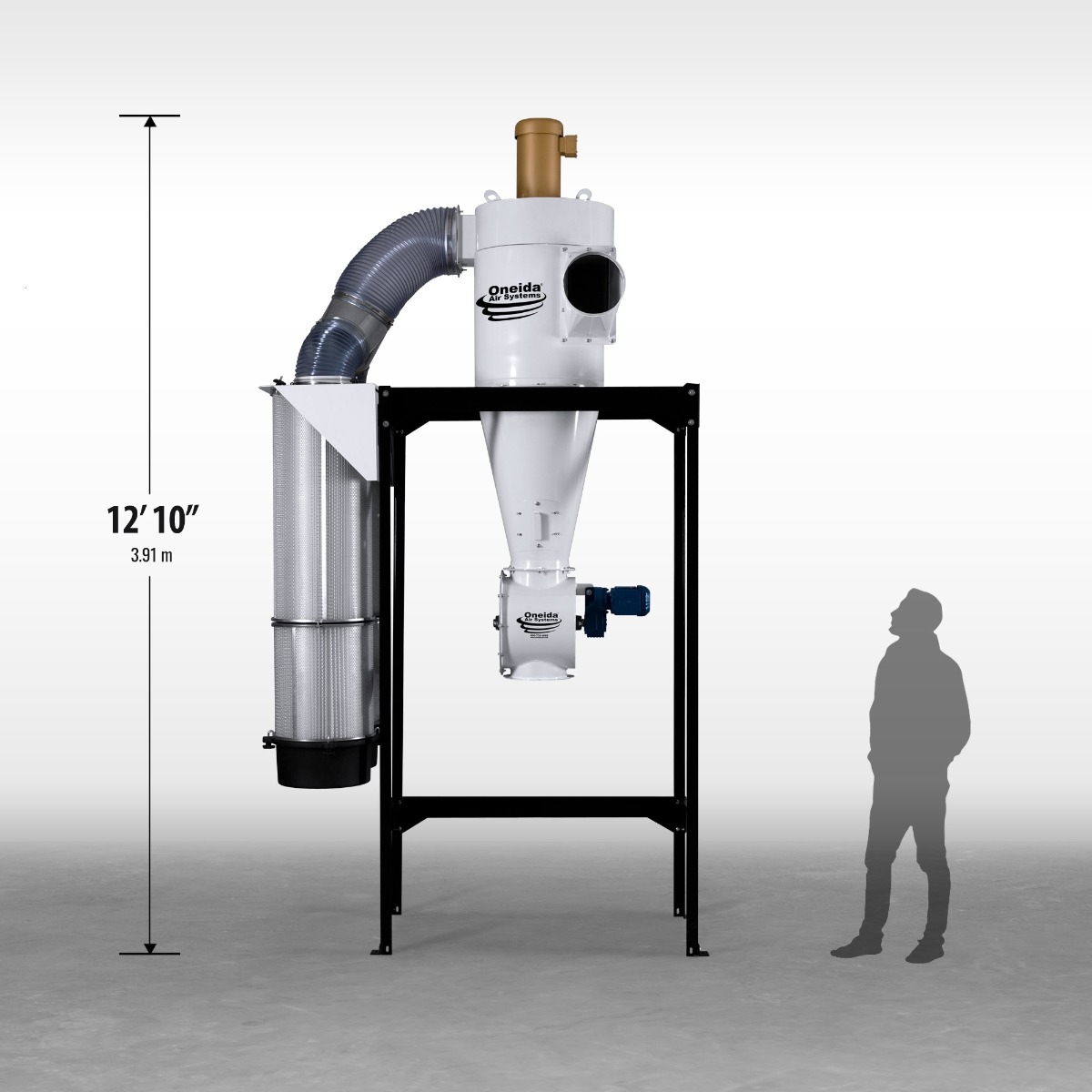

7.5HP Direct Drive Cyclone Dust Collector

$10,518.00 – $14,508.00

Industrial dust collection system for large commercial shops – suitable for collecting from multiple 4″-6″ dust ports simultaneously. Includes modular stacking filter system with efficiency gauge to alert the operator for cleaning. Full-welded, steel cyclone separator captures and removes fine dust and bulk debris from the airstream to provide continuously high suction power and reduce filter maintenance downtime. Custom choice of voltage (230V, 460V) and waste disposal configuration (55 gal., 110 gal., Air Lock, etc.).

Usually ships in 2-4 weeks| Power Configuration | 230V, 460V |

|---|---|

| System Configuration | Freestanding Leg Kit with 55-Gallon Steel Drum, Freestanding Leg Kit with Air Lock Valve and Clean-out Cone, Freestanding Leg Kit with Dual 55-Gallon Steel Drums |

Recommended Product

-

-

-

$99.95

$99.95 -

$4499

$4499 -

$499

$499 -

$1199

$1199 -

$85

$85 -

-

$119.95

$119.95 -

-

-

$999

$999 -

$499

$499 -

-

-

$199

$199

Description

Realize the Power of American Manufacturing

Our 7.5HP Direct Drive system is the workhorse of our industrial line of cyclonic dust collection systems – delivering maximum airflow performance within a compact, quiet, and cost-effective package. Built to last a lifetime using industrial, heavy-gauge steel components, our 7.5HP is ideal for commercial shops with fixed ductwork and multiple tools in use simultaneously.

This system can be configured in a variety of ways to meet the needs of your shop. See the system options section below for further details.

Included Features & Components

- Industrial 7.5HP U.S. Made Motor

- Backward Inclined, Non-Sparking, Cast-Aluminum Impeller

- High-Efficiency 230V (or 460V) 3-Phase Power

- Magnetic Starter with Overload Protector

- Heavy-Gauge Solid Welded Steel Cyclone Separator with Clean-Out Access Door

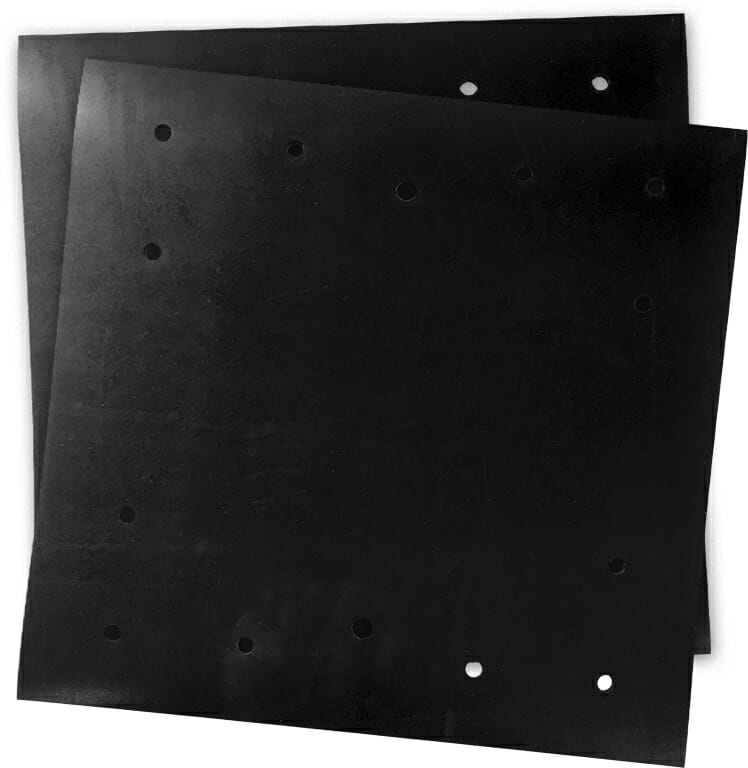

- Modular Stacking Spunbond Cartridge Filters

- Real-time Filter Efficiency Pressure Gauge

- Drop-In Acoustic Foam Filter Silencers

- Industrial Angle Iron Frame Stand

- Choice of 55-Gallon, 110-Gallon, Custom Sized Waste Bin

- 2 Year Limited Warranty

Configurable Waste Containment Systems

Whether your system is connected to just a few saws, drum sanders, or industrial CNC equipment, Oneida Air Systems recognizes that the amount of waste produced by shops can vary significantly; We offer a wide variety of waste handling accessories to suit the needs of any work environment. All options are mounted to a highly durable, angle iron stand with a rust-preventative, powder coat finish.

- Air Lock Model: Ideal for shops with large amounts of waste production and provides the most cost effective and convenient disposal option. The dust collector can operate continuously while dust and debris is automatically fed to the container below, eliminating downtime for emptying. The customer must supply their own waste container for the system.

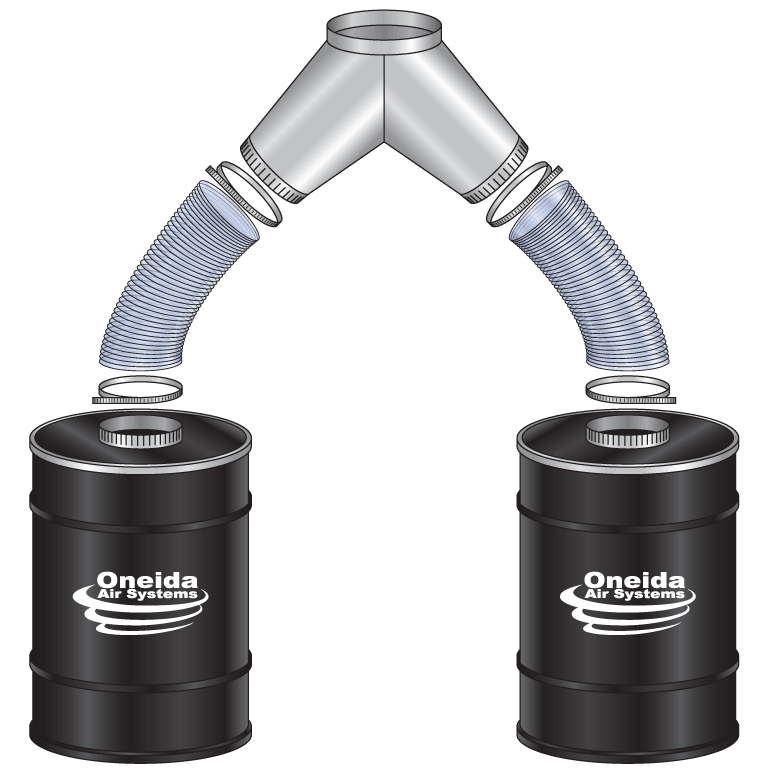

- Dual Drum Model: Ideal for any shops with varying quantities of waste production. Waste is deposited evenly between both 55 gal. drums, doubling the time needed between emptying. The system must be powered down to empty either drum.

- Single Drum Model: Ideal for smaller commercial shops with a strict height restriction or limited waste production. Expect to empty the single 55 gal. drum much more frequently if used with a large planer, drum sander, or CNC machine.

Features

Specifications

| Horsepower | 7.5HP |

| Motor Type | U.S. TEFC Motor |

| Motor Service Factor | 1.15 |

| Voltage | 208-230V, 460V |

| Recommended Breaker Size | Call for Info |

| Amperage (Typical) | 19-17.2A 8.6A @ 460V |

| Phase (Pre-Wired) | 3-Phase |

| Frequency | 60Hz |

| Power Connector | Bare Wiring Three Hot Wires & Ground |

| Impeller Type | Single-piece, backward inclined, non-sparking/non-ferrous, cast aluminum alloy. |

| Impeller Size | 16-1/2" Dia. |

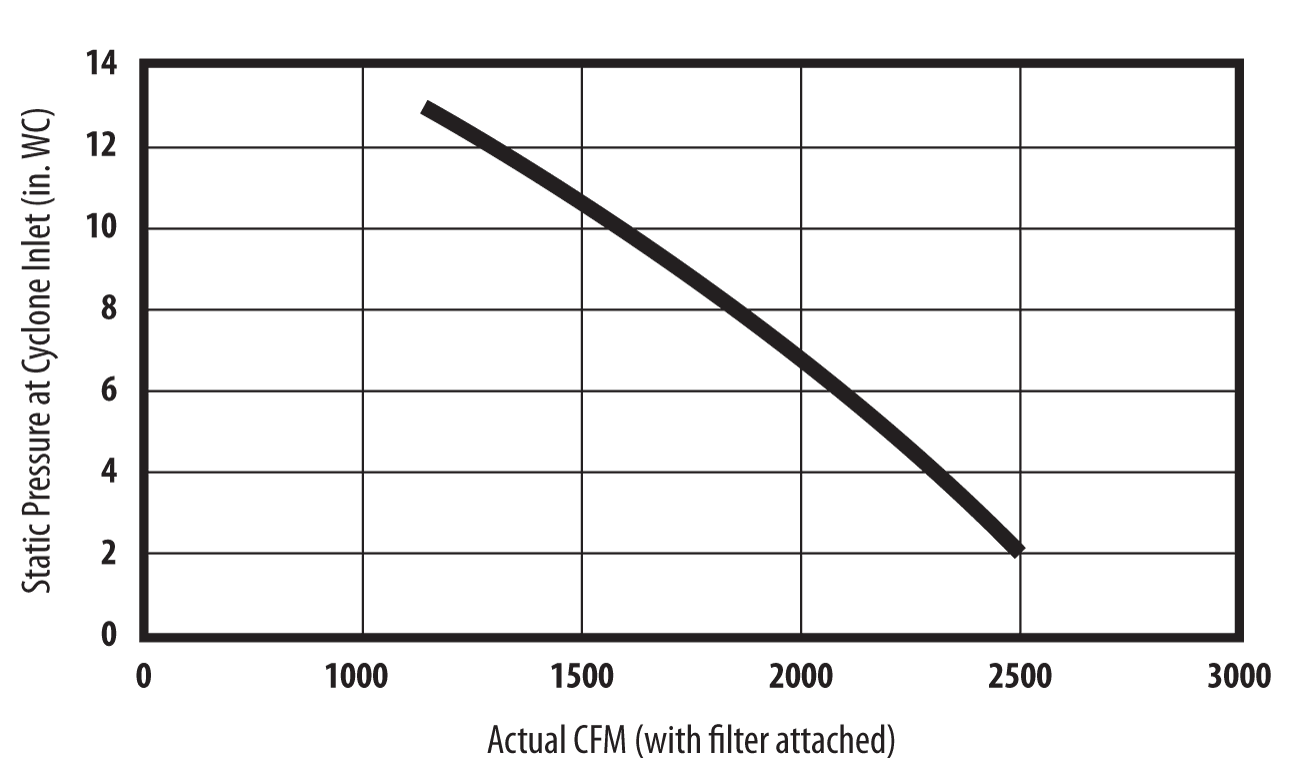

| Real CFM Rating | 2,514 Actual CFM at 1.5" S.P. |

| Free Fan CFM Rating | 4,080 CFM |

| Maximum Suction | 14" WC |

| Max. Open Blast Gates | 4 Gates |

| Noise Level | 83 dBA @ 10 ft |

| Filter Type | Izumi Axtar Spunbond Media |

| Filtration Efficiency | 99.9% @ 0.2-2.0 microns |

| MERV Rating | MERV 13 ± |

| Total Filtration Area | 310 sq ft |

| Waste Capacity | Customizable |

| Remote Control Part # | For 208-230V: Item #AK N/A for 460VR220003 |

| Primary Build Materials | Cold Rolled Steel |

| Welding | Seam Welded |

| Static Resistance Rating | Conductive (Metal) |

| Color | White |

| Inlet Size | Round: 10" Dia.Square ID: 6-7/8"(W) x 13-13/16"(H)Square OD: 9-1/4"(W) x 16-3/8"(H) |

| Outlet Size | Round: 12" Dia.Square ID: 10"(W) x 7-1/2"(H) |

| Discharge Size | 10" Dia. |

| Width | 80.3" |

| Depth | 39.2" |

| Height | Position 1: 151-13/16"Position 2: 137-13/16"Position 3: 127-13/16" |

| Contents | Blower Motor Assembly, Magnetic Starter, Fan Housing, Cyclone Separator, Square-to-Round Inlet Adapter, Filter Plenum, 4x Modular Cartridge Filters, Filter Efficiency Gauge, Angle Iron Stand, Hardware. Choice of Drum, Dual Drum, or Air Lock Valve. |

| Country of Manufacture | United States |

| Warranty Information | 2 Year Limited Warranty |

| Certifications | Complete system is cETLus certified for indoor use |

| Applicable Patents | U.S. Patents #7247180, #9370740 |