5HP High Vacuum Cyclone Dust Collector

$7,818.00

High static air pressure system for CNC, sanding, and other fine dust applications. Complete system includes heavy-gauge steel cyclone, U.S. made motor, spunbond cartridge filter, angle frame stand, 55 gallon dust bin, filter gauge, and more.

Usually ships in 2-4 weeks| Phase (Pre-Wired) | 1-Phase, 3-Phase |

|---|---|

| Power Configuration | 230V, 460V |

Recommended Product

-

-

-

$119.95

$119.95 -

-

$654

$654 -

-

-

$89.95

$89.95 -

-

$999

$999 -

$499

$499 -

-

-

-

$651

$651

Description

High Vacuum Pressure Dust Control for Industrial CNC Cutting Tools

Our 5HP High-Vacuum Dust Collector is one of our most powerful professional dust collection systems and is designed for small to medium sized shops running tools, such as CNC machines, where a high amount of static pressure is needed to adequately collect airborne dust. The unique configuration of our High-Vacuum systems make full use of the high-efficiency U.S. motor and cyclone separator to deliver maximum static pressure to multiple tools simultaneously.

This high pressure system is ideal for use with any type of CNC cutting tools as well as saws, jointers, lathes, shapers, planers, routers, sanders, and more!

Included Features & Components

- Industrial 5HP U.S. Made Fan Blower Motor

- Magnetic Starter w/ Overload Protector

- Heavy-Gauge Seam Welded Steel Cyclone Separator

- High-Efficiency Modular Cartridge Filters

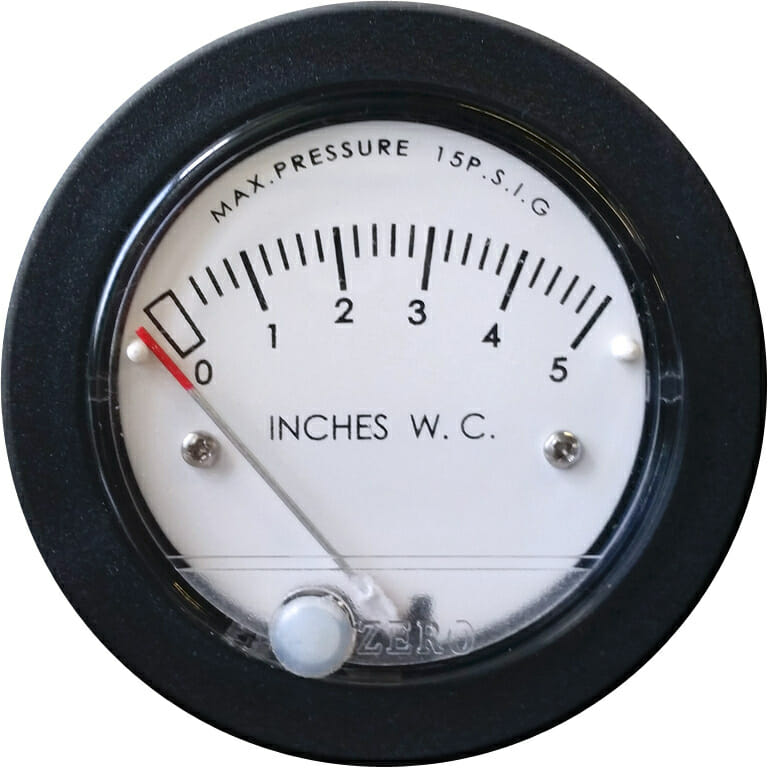

- Real-time Filter Efficiency Gauge

- Internal Foam Silencer

- Compact, Heavy-Duty Steel Angle Frame Stand

- 55-Gallon Reinforced Steel Dust Bin

- D.I.Y. Ductwork Design Guide

- 2 Year Limited Warranty

Features

Specifications

| Horsepower | 5HP |

| Motor Type | U.S. TEFC Motor |

| Motor Service Factor | 1ph: 1.00 | 3ph: 1.15 |

| Voltage | 208-230V |

| Recommended Breaker Size | 30A |

| Amperage (Typical) | 1ph: 19.5A3ph: 12-11.8A (5.9A @ 460V) |

| Frequency | 60Hz |

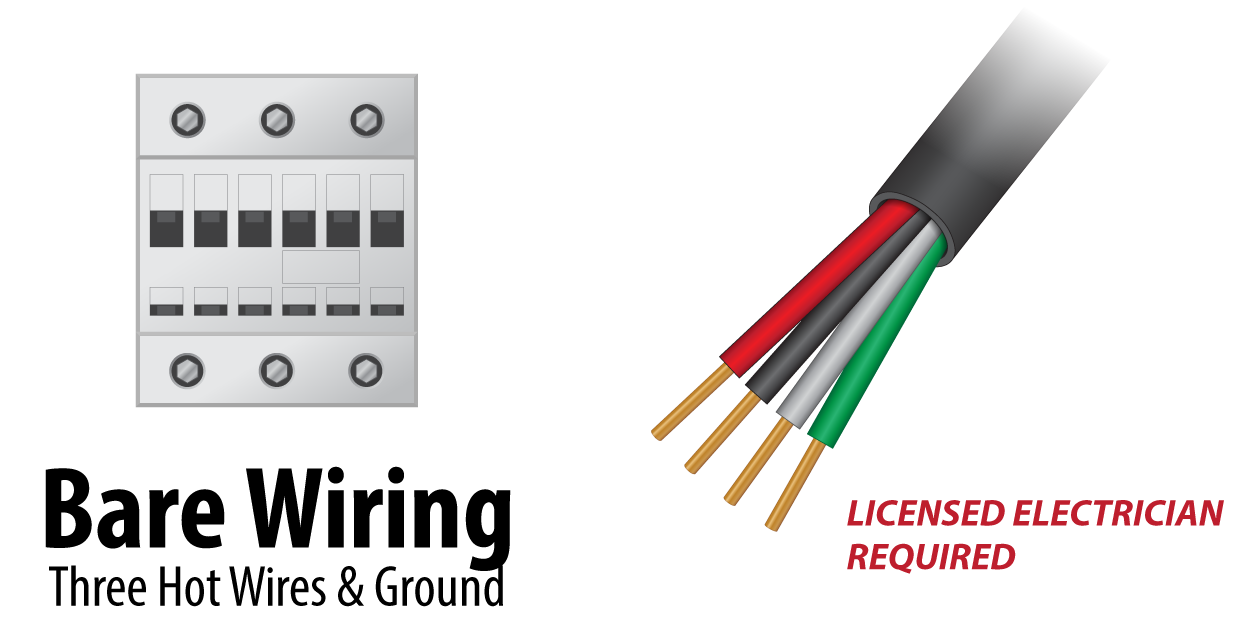

| Power Connector |

|

| Power Cord Length | 10 feet |

| Impeller Type | Single-piece, backward inclined, non-sparking/non-ferrous, cast aluminum alloy. |

| Impeller Size | 16-1/2" Dia. |

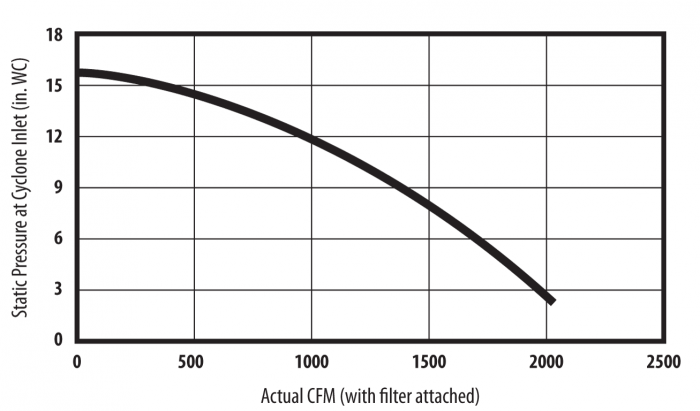

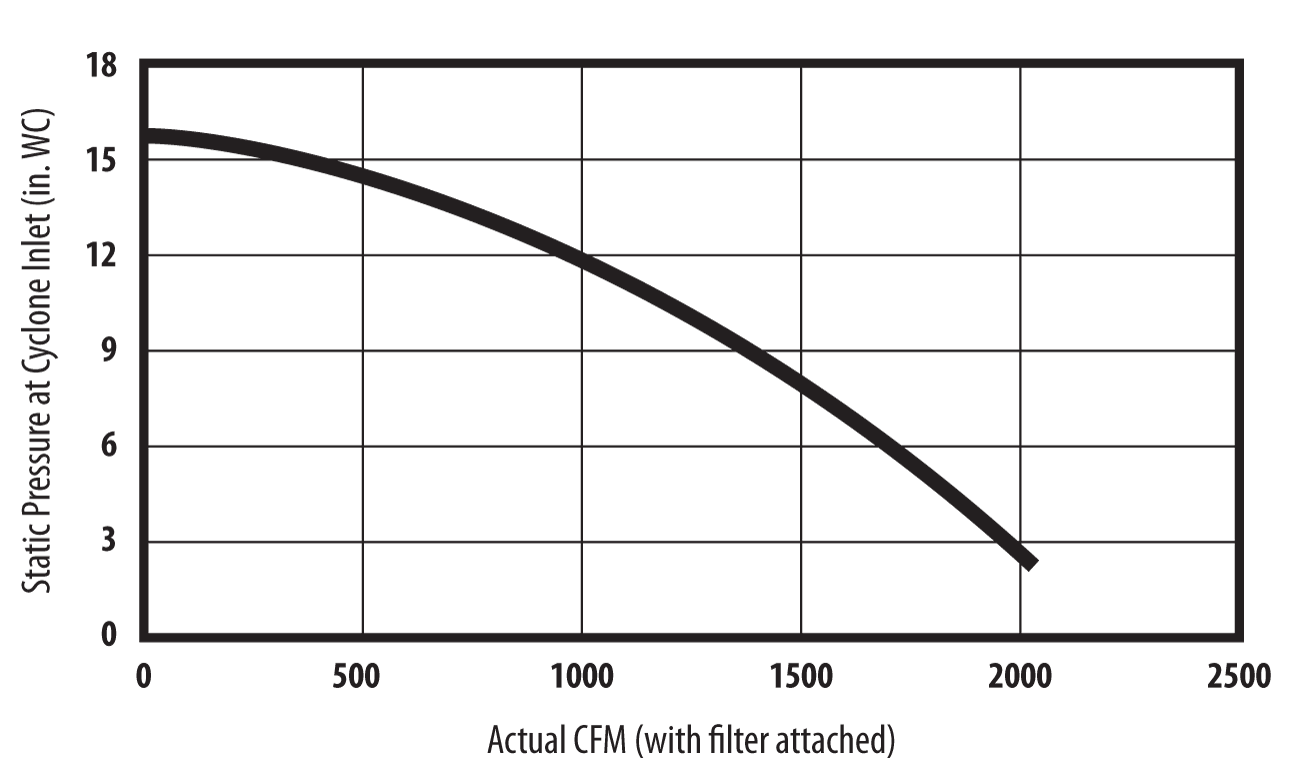

| Real CFM Rating | 2,150 Actual CFM at 2" S.P. |

| Free Fan CFM Rating | 3,225 CFM |

| Maximum Suction | 16" WC |

| Noise Level | 75-81 dBA @ 10 ft |

| Filter Type | Izumi Axtar Spunbond Media |

| Filtration Efficiency | 99.9% @ 0.2-2.0 microns |

| MERV Rating | MERV 13 ± |

| Total Filtration Area | 155 sq ft |

| Waste Capacity | 55 Gallons |

| Remote Control | Sold Separately |

| Remote Control Part # | 1ph: Item #AXR2200003ph: Item #AKR220003 |

| Primary Build Materials | Cold Rolled Steel |

| Welding | Seam Welded |

| Static Resistance Rating | Conductive (Metal) |

| Color | White |

| Inlet Size | 8" Dia. |

| Outlet Size | Square ID: 10.031" (W) x 7.64" (H) with 1.25" Flange |

| Discharge Size | 10" Dia. |

| Width | 59" w/ Filter |

| Depth | 31" |

| Height | 109.5" |

| Height to Center of Inlet | 80" |

| Contents | Blower Motor Assembly, Magnetic Starter, Fan Housing, Cyclone Separator, Filter Plenum, 2x Stacking Cartridge Filters, Internal Silencer, Filter Efficiency Gauge, Drum, Stand, Hardware |

| Country of Manufacture | United States |

| Warranty Information | 2 Year Limited Warranty |

| Certifications | Complete system is cETLus certified for indoor use |

| Applicable Patents | US Pat. #7247180, #9370740 |