What Language Does a CNC Machine Use? You Guide to Understanding the Basics of CNC Programming

When you are looking to learn how to use a CNC machine, it is important to understand the basics of how it works and what language is used to control the machine. Though a full understanding of programming language may not be necessary for operations, a general understanding of how a CNC router works is often helpful. But what language does a CNC machine use anyways?

When you are looking to learn how to use a CNC machine, it is important to understand the basics of how it works and what language is used to control the machine. Though a full understanding of programming language may not be necessary for operations, a general understanding of how a CNC router works is often helpful. But what language does a CNC machine use anyways?

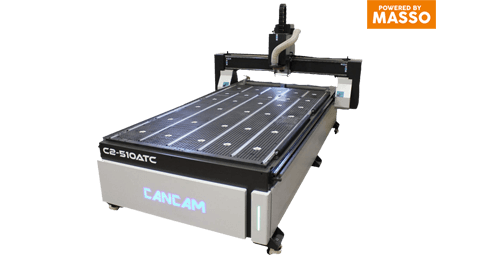

At CanCam, we are proud to be your premier source for commercial CNC machines for sale in Canada. We know that getting started in the CNC machining industry can come with a learning curve and programming languages are no exception. In this post we answer common questions including what is G code in CNC machine and what language does a CNC machine use, to help you have a more solid understanding of how a CNC machine works.

If you are looking to learn more about how to get into the CNC machining industry our post, What is CNC Machining? What You Should Know about CNC Machines and the CNC Machining Industry offers helpful insight into the industry.

What Language Does a CNC Machine Use?

To use a CNC machine, you’ll need to use code, otherwise known as language, to tell the machine what to do. When it comes to CNC machines, G-code and M-code are the most common languages, though these programming languages are not the only types. Some machines may use proprietary languages in their operations, while others will use more conversational programming that can be more intuitive for less experienced operators.

To understand how to use your machine, you will first need to know the type of language it uses. Though G-code is the most common language for CNC machines, it may not be the one used by your specific CNC router. When looking for a small shop CNC machine, you’ll want to be certain that you can operate the machine effectively. Learning the basics of the required programming language is a great way to boost your success.

What’s The Difference Between G Code and M Code?

Now that you know a bit more about what programming language a CNC machine uses, you’ll want to be able to answer the question, what is M-code in a CNC machine, and what is G-code for a CNC machine. G-code primarily deals with the movement and positioning of a CNC machine, while M-code is related to auxiliary functions. Simply put, G-code tells a CNC machine how to move while M-code takes care of other operational functions, such as changing a tool.

It may not be necessary for a CNC machine operator to understand the ins and outs of G-code and M-code. Yet knowing what they are and how they differ is important when it comes to your overall understanding of how a CNC router works.

Do I Need to Know G-Code to Use a CNC Machine?

It is a good idea to have a basic understanding of the programming language your CNC router uses. However, it may not be necessary for you to have a detailed understanding of how the code works or how to write it. Software such as CAM software is often used to create toolpaths without needing to directly write G-code which can eliminate the need-to-know G-code altogether. However, in order to make manual adjustments, understanding how to write G-code can be extremely helpful.

There is a lot to consider when looking to add a CNC router to your workshop and the language your CNC router uses is an important factor to understand. If you are looking to learn more about CNC routers and how to use them, our post, Everything You Should Know about Becoming a CNC Machine Operator, provides helpful insight.