Vertical Milling Machines: What They Are and How Your Workshop Can Benefit from Having One

When it comes to selecting a CNC router for your workshop, there are many factors that you’ll need to consider, as not all router types will be appropriate for your needs. Vertical milling machines are one of the most popular options for CNC routers, and for good reason too. These machines offer extensive versatility, are generally affordable, and can be used for a wide range of industries. But what exactly is a vertical milling machine, and why should you consider one for your workshop?

When it comes to selecting a CNC router for your workshop, there are many factors that you’ll need to consider, as not all router types will be appropriate for your needs. Vertical milling machines are one of the most popular options for CNC routers, and for good reason too. These machines offer extensive versatility, are generally affordable, and can be used for a wide range of industries. But what exactly is a vertical milling machine, and why should you consider one for your workshop?

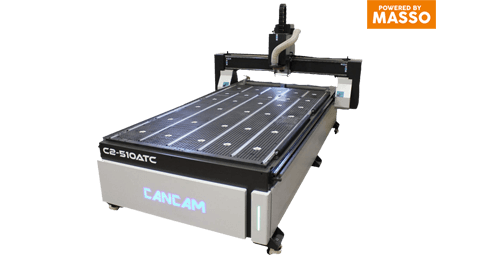

At CanCam, we are proud to be your premier source for commercial CNC machines for sale in Canada. We know that CNC routers and milling machines can be invaluable when it comes to increasing productivity and precision in your workshop. In this post, we explore the basics and show you why a CNC vertical milling machine might be a game changer for your workshop.

What is a CNC Vertical Milling Machine?

When you want to know, what is a vertical milling machine, the answer is fairly straightforward. In the most basic sense, a CNC vertical milling machine is a tool that uses a spinning cutter mounted vertically to remove material from a workpiece and in turn, shape it. A CNC vertical milling machine consists of various components, including a spindle, table, column, saddle and knee, base, and controls.

To understand how a vertical milling machine works, you’ll want to be familiar with CNC machining processes. To operate a vertical milling machine, you’ll start by securing the workpiece to a movable table below the cutter. This table can be moved up, down, and sideways, bringing the material to the cutter, and it will then create the desired shapes and surfaces as outlined by the design inputted into the computer software.

Our post, What is CNC Machining? What You Should Know about CNC Machines and the CNC Machining Industry offers more insight into CNC machine processes and how a beginner can get into the industry.

What is a Vertical Milling Machine Used For?

When wondering, what does a vertical milling machine do, there are truly endless possibilities. Some of the processes that a vertical milling machine can do include face milling, slotting and keyways, drilling and boring, contouring, and engraving. Vertical milling machines are used in a wide range of industries, including the automotive, aerospace, medical and consumer product industries. A vertical milling machine is generally used to create parts and components that require precision, such as for airplane parts, engine components, and surgical tools.

What is The Difference Between Horizontal and Vertical Milling Machines?

The main difference between horizontal and vertical milling machines is simply the orientation of the spindle. However, it’s important to note that the type of operations each machine is best for can vary. Horizontal milling machines are generally considered to be more heavy-duty and can come at a higher cost, while vertical milling machines are more affordable.

When it comes to determining which machine type is best for your workshop, you’ll need to consider the unique needs of your shop and what type of applications you need a CNC router for. At CanCam, we would be pleased to help you find an industrial CNC router that is best suited to the needs of your shop. Whether you are looking to make a move to a CNC router for the first time or are looking to further expand the capabilities of your workshop, we have the experience to help you pick an excellent and versatile choice that perfectly matches your needs.

For more information on why a CNC router could make a significant difference for your workshop, see our post, Why a CNC Machine Can Make All the Difference for Your Furniture Makings Startup.