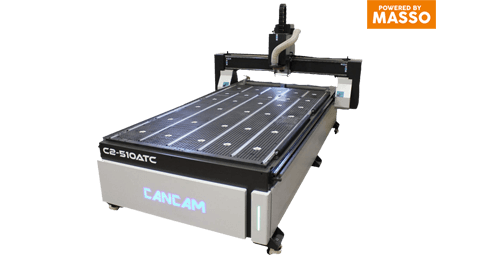

Considering a Vacuum Table?

There is always a debate about whether or not to have a vacuum table top for your CNC or whether to stick with a t-slot table. In reality it will be more expensive to get the vacuum table and depending on what you’re using your CNC machine for as you may not need it. But nobody can deny that it will increase the value of your machine, as well as vastly increase your efficiency.

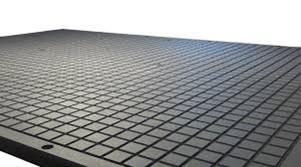

Providing you are using your machine regularly a vacuum table is an immediate boost to your efficiency. No more wasting time clamping down materials and finding ways to clamp small materials. No more having to deal clamps marking up your material either, it’s just a simple task of placing the material on the table, turning on the vacuum pump and getting to work. You can get more work done and have an easier and more enjoyable time doing so.

A vacuum table can only be made useful by its vacuum pump and picking out a vacuum pump can be a confusing task for many people as it is not a very standard category of knowledge. Our quick recommendation is a Becker brand vacuum pump. They have multiple sizes and powers but they are known for their quality pumps. You want to make sure your pump is recommended for your table size. If you purchase a pump that is for a 4’x4’ table and you own a 5’x10’ table, then you are going to have issues holding down your materials. The pumps power is now being spread through a 5’x10’ table rather than a single 4’x4’ area, resulting in a major decrease in resistance. Always ensure the pump is recommended at your table size.

I feel that a vacuum pump is always the way to go. You can also get a vacuum t-slot combo table that would allow you to use t-slots for clamping but have the capability to one day utilize the vacuum technology when you are ready to make the purchase and get yourself that pump. Either way, consider the vacuum table when making a purchase. It’s a purchase that sucks, in a good way.

For more info on becker pumps check out this pdf.